For those in the construction industry, the efficiency of operations can often hinge on the tools and equipment at their disposal. Among these, the mobile asphalt mixing plant stands out as a versatile and essential component, particularly for projects requiring on-site production of asphalt.

Understanding the Mobile Asphalt Mixing Plant

Before delving into the installation process, it’s crucial to grasp the significance of a mobile asphalt mixing plant. Unlike traditional fixed plants, an asphalt mobile plant offers unparalleled flexibility, allowing operators to relocate it as needed, minimizing transportation costs and maximizing productivity.

Installation Essentials

Installing a mobile asphalt mixing plant involves several key steps, each crucial for ensuring optimal performance and longevity.

Site Preparation

Begin by selecting an appropriate location for the asphalt plant, considering factors such as accessibility, terrain stability, and proximity to the construction site. Ensure the area is level, free from obstructions, and equipped with adequate drainage to prevent water accumulation.

Foundation Construction

Next, construct a sturdy foundation to support the weight of the plant and facilitate efficient operation. This may involve laying a concrete pad or using specialized foundation materials tailored to the specific requirements of the mobile asphalt plant.

Assembly and Installation

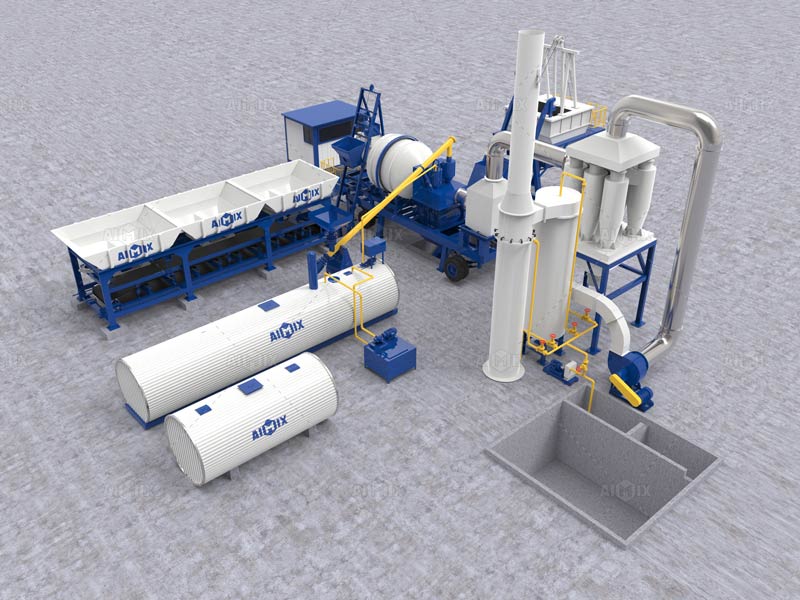

With the foundation in place, proceed to assemble the various components of the mobile asphalt mixing plant. This typically includes the main unit, storage tanks, conveyor systems, and control panel. Ensure each component is securely fastened and properly aligned to prevent operational issues.

Connectivity and Calibration

Once assembled, connect the necessary utilities such as power, water, and fuel lines to the plant. Take care to follow manufacturer guidelines and industry best practices to ensure safe and reliable operation. Additionally, calibrate the asphat mixng plant portable‘s settings and controls to optimize performance and meet project specifications.

Benefits of a Mobile Asphalt Mixing Plant

Investing in a mobile asphalt mixing plant offers numerous benefits for construction companies and contractors. Here are the benefits of investing in asphalt batching mix plant.

- Flexibility to produce asphalt on-site, reducing transportation costs and logistics challenges.

- Rapid deployment and setup, minimizing downtime and accelerating project timelines.

- Ability to adjust production capacity based on project requirements, maximizing efficiency and resource utilization.

- Enhanced control over asphalt quality and composition, ensuring compliance with industry standards and client expectations.

- Cost-effective solution for small to medium-scale projects, eliminating the need for large, fixed infrastructure investments.

Conclusion

Installing a mobile asphalt mixing plant involves careful planning, meticulous execution, and a commitment to quality. By following the outlined steps and harnessing the benefits of hot mix asphalt plant, construction professionals can streamline operations, boost productivity, and achieve greater success in their projects.

For those seeking a reliable and efficient solution for asphalt production, a mobile asphalt mixing plant represents not just a piece of equipment, but a strategic investment in the future of construction.