Typically, cement concrete brick making machines are machines that use both pressure and vibration on the mortar in order to create hollow concrete blocks, also known as hollow cement blocks or cement concrete bricks. The machine has many different capacities and automation levels. The following will describe some of these levels and capacities in greater detail.

Some may wonder why these types of cement concrete brick making machines are often referred to cement bricks instead of cement concrete bricks. The honest truth is that many people do not know the difference between the two materials.

Cement is a powder material that is often used along with water and other types of raw materials in order to create concrete.

Before hollow blocks were used, it was common to only use bricks. However, once hollow cement concrete blocks became more widely recognized, they were then referred to as cement bricks.

In other words, the terms ‘hollow brick machine’, ‘block making machine’ and ‘interlocking brick machine’ are all interchangeable.

The Brick Making Process

Now let us delve a little deeper into the operational process of making these types of bricks. These machines are usually divided into two separate categories. The categories are:

– Stationary cement concrete brick making machine

– Mobile cement concrete brick making machine

What Are Stationary Cement Concrete Brick Making Machines?

As the name implies, this type of machine does not move. It is designed to create different types of products and capacities. This type of machine uses molds and pallets in order to create cement blocks and other products made from cement.

The aggregate is first transferred in order to supply the machine with materials. The machine then manually or automatically transports the aggregate to the machine’s mixer. The cement and water are also placed inside of the mixer. This is when the mortar forms.

This mortar is then taken to the brick making machine, and the machines uses pallets and molds to create the hollow concrete blocks.

After these blocks have been formed, they require time to dry so that they can be of the most use to the end user.

Many stationary cement concrete brick making machines offer some options that can be included when an order is placed. For example, customers can choose to add another hopper to the machine.

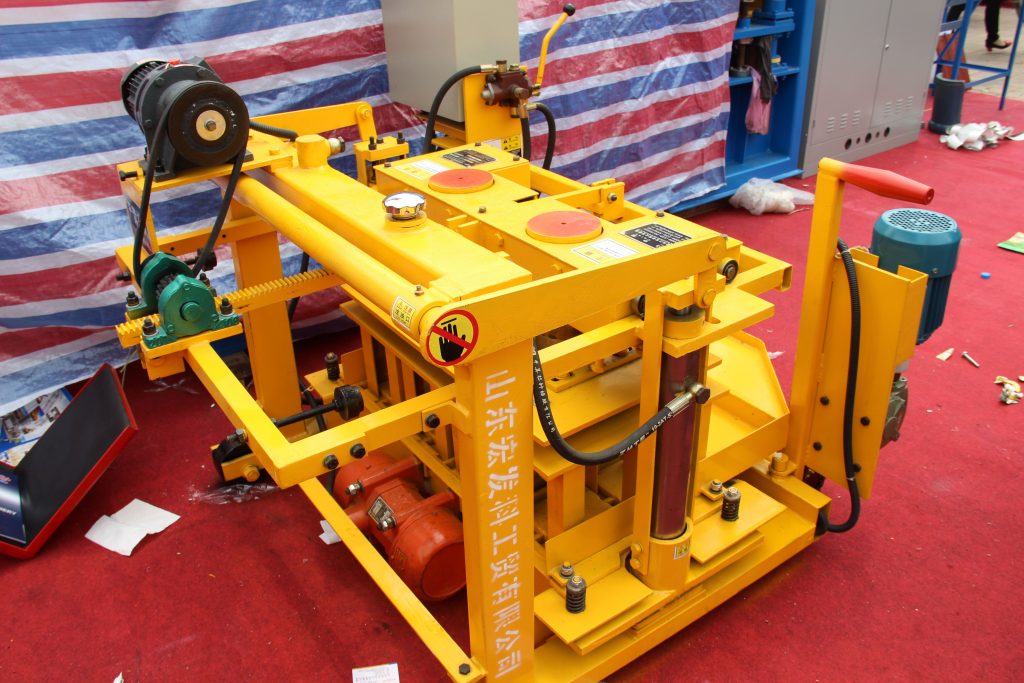

What Is A Mobile Cement Making Machine?

This machine is often referred to as the ‘egg laying machine’. This is due to the fact that many consider it much easier to operate than stationary cement concrete brick making machines.

These machines are also a lot cheaper than the stationary machines. However, there capacity is also a lot lower. The machine is able to move once the cement bricks have been laid.

When it comes to the advantages and disadvantages, this machine becomes mobile after the concrete blocks are laid. It also does not need pallets because the blocks are produced on the ground.

Unfortunately, this machine cannot create concrete paving blocks because it is not considered a paver block machine.

These are some of the factors that you will need to consider if you are considering investing in a cement concrete brick making machine. Choose the brick machine that best meets your company’s budget and needs.