Double girder gantry cranes are vital equipment in industries requiring heavy lifting and material handling capabilities. Understanding their design and functionality is crucial for maximizing efficiency, safety, and productivity in various applications. In this article, we will delve into the intricate details of double girder gantry cranes, exploring their design features, operational principles, and factors influencing their functionality.

Design Features

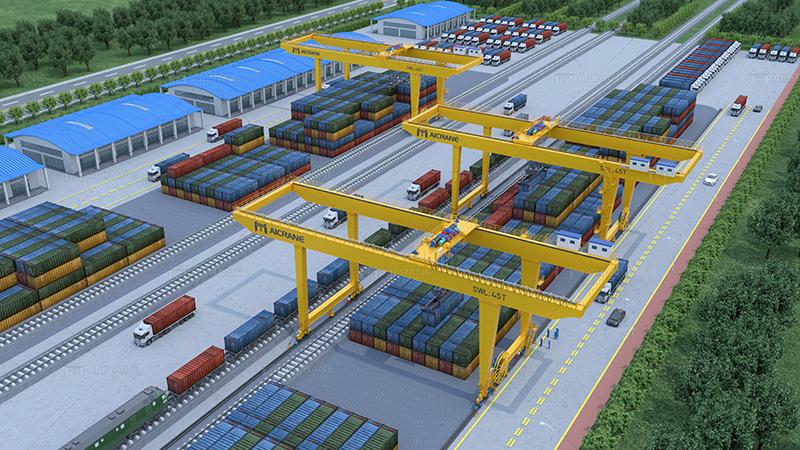

Double girder gantry cranes feature a robust structural design comprising two horizontal girders supported by vertical legs, forming a stable gantry framework. These cranes are typically larger and more powerful than single girder gantry cranes, allowing for higher lifting capacities and longer spans. The double girder configuration provides increased stability, stiffness, and resistance to deflection under heavy loads, making them suitable for demanding industrial environments.

Functionality

Double girder gantry cranes are versatile lifting solutions capable of handling a wide range of materials and loads. Their primary function is to lift and transport heavy objects horizontally within a defined workspace. With their high lifting capacities, double girder gantry cranes(двухбалочный козловой кран) are commonly used in applications such as shipbuilding, construction, manufacturing, and logistics. They excel in tasks requiring precision, efficiency, and reliability, thanks to their robust construction and advanced control systems.

Operational Principles

The operation of double girder gantry cranes involves several key principles governing their functionality. Electric hoists mounted on trolleys traverse along the girders, enabling vertical lifting and horizontal movement of loads. Control mechanisms, such as pendant controls or radio remotes, allow operators to precisely maneuver the crane and position loads with accuracy. Safety features, including overload protection systems, limit switches, and emergency stop buttons, ensure safe operation and prevent accidents.

Factors Influencing Functionality

Several factors influence the functionality and performance of double girder gantry cranes. Lifting capacity is a crucial consideration, with cranes available in various capacities ranging from a few tons to several hundred tons. Span width and height clearance are other critical factors, determining the crane’s coverage area and ability to navigate obstacles. Environmental conditions, such as temperature extremes, wind loads, and corrosive atmospheres, also impact crane operation and require appropriate design considerations.

Price of Gantry Crane

The price of a double girder gantry crane varies depending on several factors, including lifting capacity, span width, height clearance, and additional features. A 50-ton double girder gantry crane(козловой кран 50 тонн) with a large span width and advanced control systems will typically command a higher price than a smaller capacity crane with basic functionalities. However, investing in a high-quality gantry crane tailored to specific operational requirements can result in long-term cost savings through improved efficiency, reliability, and productivity.

Structural Components

Double girder gantry cranes are engineered with precision to withstand heavy loads and harsh operating conditions. The horizontal girders, typically made of steel beams, provide the main support structure for the crane. These girders are connected to vertical legs or columns, which are securely anchored to the ground to ensure stability. Diagonal bracing and cross beams are often incorporated into the design to enhance structural integrity and distribute load forces effectively. Additionally, end carriages house the trolley and hoist assembly, allowing for smooth movement along the girders.

Control Systems

Modern double girder gantry cranes are equipped with advanced control systems that enable operators to maneuver loads with precision and efficiency. These control systems may include pendant controls, radio remotes, or cabin-mounted control panels, depending on the crane’s specifications and application requirements. Variable frequency drives (VFDs) provide smooth acceleration and deceleration, reducing wear on components and improving energy efficiency. Programmable logic controllers (PLCs) offer customizable functionality, allowing for automated operation and integration with other industrial systems. Visit website:https://gantrycrane.kz/

Safety Features

Safety is paramount in the design and operation of double girder gantry cranes to prevent accidents and protect personnel and property. These cranes are equipped with a range of safety features, including overload protection systems, which prevent the crane from lifting loads exceeding its rated capacity. Limit switches are installed to prevent collisions and limit the travel of the trolley and hoist. Emergency stop buttons allow operators to quickly halt crane operation in case of emergencies. Additionally, audible and visual warning devices alert personnel to potential hazards, such as approaching crane movements.

Double girder gantry cranes are sophisticated lifting solutions designed for heavy-duty industrial applications. Understanding their design features, functionality, operational principles, and factors influencing functionality is essential for selecting the right crane for a particular application. While the price of a gantry crane(Козловые краны купить) is a significant consideration, it should be balanced with considerations of lifting capacity, span width, height clearance, and environmental factors to ensure optimal performance and cost-effectiveness in the long run. By leveraging the capabilities of double girder gantry cranes, industries can enhance their material handling capabilities and streamline their operations for greater efficiency and productivity.