Mines, whether they are deep underground or open-pit, are intricate and demanding environments that require a myriad of specialized equipment to operate efficiently and safely. Among these crucial tools is the mine winch, a powerful piece of machinery that plays a pivotal role in the extraction of valuable minerals and ores. In this article, we will delve into the working principle of mine winches, exploring their importance, components, and how they enable miners to carry out their tasks effectively.

The Significance of Mine Winches

Mine winches are an indispensable part of the mining industry. They are employed for a multitude of tasks, such as hoisting ore, transporting equipment, lowering and raising personnel, and facilitating ventilation. The primary objective is to lift heavy loads from underground mining operations to the surface, ensuring the extraction process is efficient and safe.

Without winches, mining operations would be significantly hindered, leading to increased costs and potentially dangerous working conditions. Therefore, understanding the working principles of these machines is vital for maintaining the sustainability and safety of mining operations.

Components of a Mine Winch

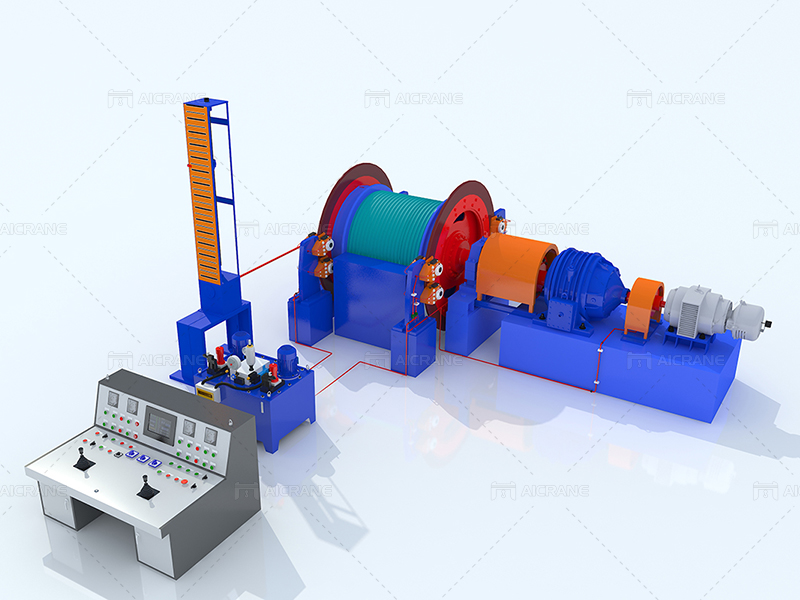

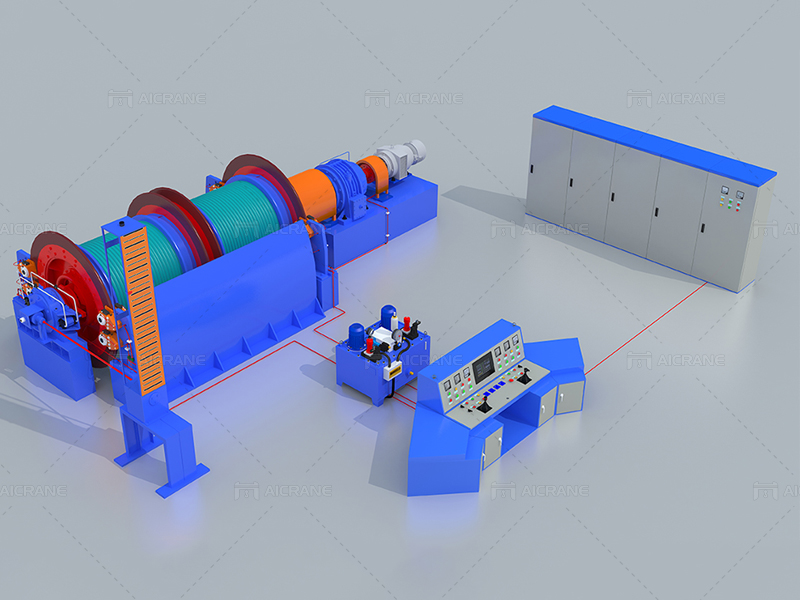

To comprehend the working principle of a mine winch, it’s important to first understand its components. A typical mine winch comprises several essential parts:

Drum: The drum is a cylindrical component around which the wire rope or cable is wound. It is the central component responsible for hoisting and lowering loads. The size of the drum determines the winch’s capacity.

Wire Rope or Cable: The wire rope or cable is wound around the drum and serves as the medium for transmitting the force applied by the winch to the load.

Motor: The motor is responsible for providing the mechanical power required to operate the winch. In many cases, electric or hydraulic motors are used, depending on the specific application and mine requirements.

Gearbox: The gearbox is used to control the speed and torque of the winch. It allows for adjustments to match the demands of the load being lifted.

Brakes: Winches are equipped with brakes to stop the drum from unwinding unintentionally when the winch is not in operation. Brakes play a critical role in maintaining safety and control.

Control System: The control system can be manual or automated, allowing operators to manage the winch’s operation efficiently. Modern winches often come with sophisticated control systems to enhance safety and precision.

Working Principle of Mine Winches

Now, let’s explore the working principle of a mine winch system step by step:

Power Supply: The operation of a mine winch begins with the power supply, which can be an electric motor, a hydraulic system, or other sources of mechanical energy. The type of power supply depends on the specific winch design and the needs of the mining operation.

Drum Rotation: When the power supply is engaged, it drives the drum’s rotation. The motor and gearbox work in tandem to control the speed and torque, allowing for precise control of the load.

Cable Winding: As the drum rotates, the wire rope or cable is wound onto the drum. This winding action creates a connection between the winch and the load.

Load Attachment: The load to be lifted is attached to the free end of the cable. The load could be anything from ore-filled buckets to machinery or even personnel in some cases.

Lifting Operation: By manipulating the controls, the winch operator can either reel in the cable to lift the load or allow it to unwind to lower the load. The winch’s ability to control the cable’s movement is crucial for the precise positioning of heavy materials in a mine.

Brake System: The winch’s brake system plays a critical role in safety. It ensures that the cable does not unwind unintentionally, preventing accidents and damage to equipment. The brakes can be applied manually or automatically, depending on the design.

Safety Measures: In mining operations, safety is paramount. Winches are equipped with various safety features and mechanisms, such as emergency stop buttons and load limit sensors, to protect both personnel and equipment.

Monitoring and Control: Modern mine electric winches often come with advanced monitoring and control systems. These systems provide real-time data on load weight, cable tension, and other relevant parameters. This information allows operators to make informed decisions and optimize the operation for efficiency and safety.

Conclusion

The mine winch is a vital component in the mining industry, enabling the efficient and safe extraction of valuable minerals and ores from deep within the Earth. Understanding its working principle and the crucial components involved is essential for miners and operators to make the most of this machinery. By carefully controlling the power supply, drum rotation, cable winding, and employing safety features, mine winches help ensure that mining operations are both productive and secure.

As technology continues to advance, mine winches are becoming more sophisticated, with integrated control systems, automated safety features, and enhanced monitoring capabilities. These developments are paving the way for even safer and more efficient mining operations in the future, ensuring the industry’s continued growth and sustainability.