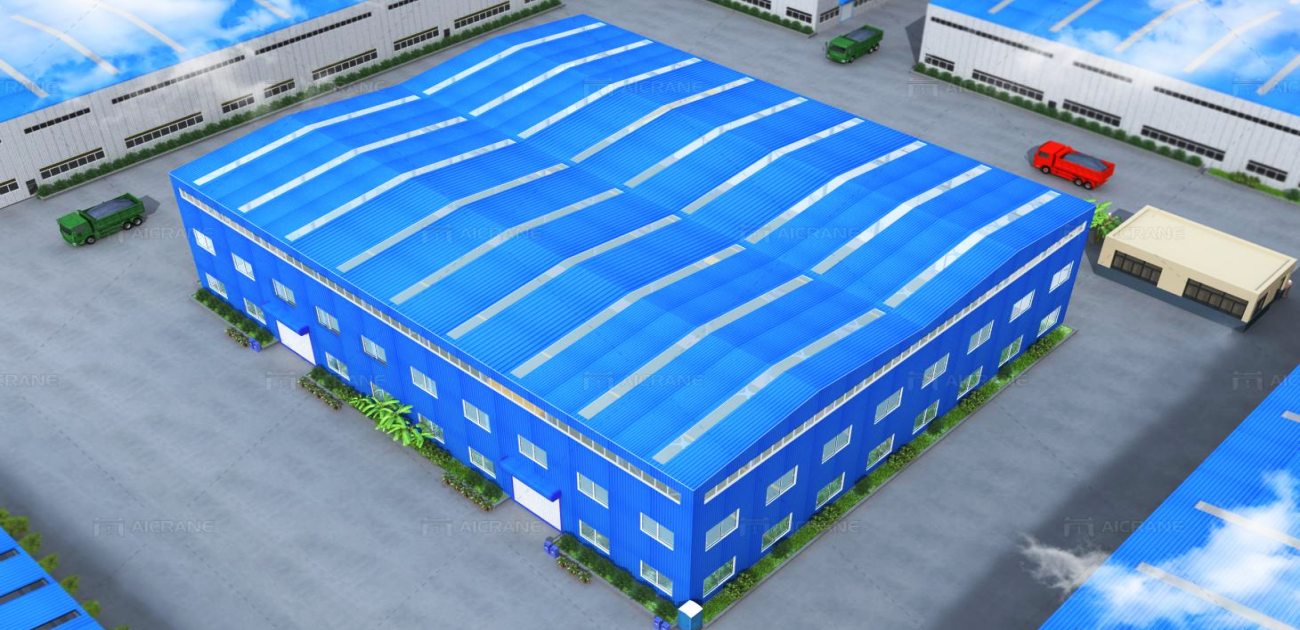

Steel building workshops have long been recognized for their superior strength, durability, and versatility. As engineering marvels, these structures exemplify the pinnacle of modern construction techniques, offering robust solutions for a wide range of industrial, commercial, and even residential applications. This article delves into the structural integrity of steel building workshops, exploring the engineering principles, benefits, and innovations that make them a preferred choice in contemporary architecture and construction.

The Engineering Principles Behind Steel Workshops

At the heart of any steel workshop’s structural integrity lies a set of fundamental engineering principles. Steel, as a construction material, offers exceptional tensile and compressive strength. This means it can withstand significant stress without deforming, making it ideal for building frameworks that require high levels of durability and resilience.

Tensile and Compressive Strength

Steel’s tensile strength allows it to endure stretching forces without breaking, while its compressive strength enables it to withstand substantial loads. This dual capability is crucial for workshops, where machinery, equipment, and materials often exert significant pressure on the building’s structure. Engineers leverage these properties to design steel frameworks that can support heavy loads and resist external forces such as wind and seismic activity.

Load Distribution

One of the key aspects of engineering a steel workshop is the efficient distribution of loads. Engineers use techniques such as trusses, beams, and columns to ensure that loads are evenly distributed throughout the structure. Trusses, for instance, provide a framework of triangular units that distribute weight evenly, reducing the stress on individual components and enhancing the overall stability of the building.

Flexibility and Adaptability

Steel’s flexibility is another significant advantage. Unlike some materials that are rigid and prone to cracking under pressure, steel can bend slightly without breaking, allowing it to absorb and dissipate energy from external forces. This flexibility is particularly beneficial in regions prone to earthquakes, where buildings must withstand dynamic forces.

Benefits of Steel Workshops

The structural integrity of steel workshops translates into numerous benefits, making them an attractive option for a variety of applications. These benefits include durability, cost-effectiveness, speed of construction, and sustainability.

Durability and Longevity

Steel is inherently resistant to many of the factors that can degrade other building materials. It is impervious to termites, mold, and mildew, and it does not warp, split, or crack over time. Additionally, with proper treatment and coatings, steel can resist corrosion, ensuring a long lifespan even in harsh environmental conditions.

Cost-Effectiveness

While the initial cost of steel may be higher than some traditional building materials, the long-term savings are significant. The durability and low maintenance requirements of steel structures reduce ongoing costs. Furthermore, the precision of steel fabrication minimizes waste, and the speed of construction reduces labor costs.

Speed of Construction

Steel workshops can be prefabricated, allowing for rapid assembly on-site. Prefabrication involves manufacturing components in a controlled environment, ensuring high quality and consistency. Once on-site, these components can be quickly and efficiently assembled, significantly reducing construction time compared to traditional building methods.

Sustainability

Steel is one of the most sustainable building materials available. It is highly recyclable, with a significant portion of new steel being made from recycled materials. This reduces the demand for raw resources and minimizes environmental impact. Additionally, steel structures are energy efficient, offering good insulation and reducing the energy required for heating and cooling. Aicrane is professional and experienced in providing sustainable and durable steel structure solutions to suit varied needs.

Innovations in Steel Workshop Design

Modern advancements in engineering and technology have further enhanced the structural integrity and versatility of steel workshops. Innovations in design, materials, and construction techniques continue to push the boundaries of what is possible with steel.

Advanced Alloys and Coatings

The development of advanced steel alloys and protective coatings has improved the performance and longevity of steel structures. These innovations enhance resistance to corrosion, wear, and environmental factors, ensuring that steel workshops remain robust and reliable over time.

Computer-Aided Design (CAD) and Building Information Modeling (BIM)

The use of CAD and BIM technologies has revolutionized the design and construction of steel workshops. These tools allow engineers to create precise 3D models of structures, optimizing the design for strength and efficiency. BIM, in particular, facilitates collaboration among architects, engineers, and construction teams, ensuring that every aspect of the project is meticulously planned and executed.

Modular Construction

Modular construction techniques have become increasingly popular in the creation of steel workshops. This approach involves manufacturing modules or sections of the building in a factory setting, which are then transported to the site and assembled. Modular construction offers several advantages, including reduced construction time, improved quality control, and minimized disruption to the site.

Case Studies: Exemplary Steel Workshops

Several notable projects highlight the engineering prowess and structural integrity of steel workshops. These case studies demonstrate the diverse applications and benefits of steel in real-world scenarios.

The Boeing Everett Factory

The Boeing Everett Factory in Washington, USA, is the largest building in the world by volume and a prime example of the capabilities of steel construction. This massive facility, used for assembling Boeing airplanes, features a robust steel framework that supports the weight of heavy machinery and large aircraft components. The factory’s design emphasizes durability, flexibility, and efficiency, showcasing the strengths of steel as a construction material.

The Crystal Palace

Originally constructed in 1851 for the Great Exhibition in London, the Crystal Palace was an iconic example of early steel and glass architecture. Although it no longer exists, its innovative design set a precedent for future steel structures. The Crystal Palace’s use of prefabricated steel structure components allowed for rapid construction and demonstrated the material’s potential for creating large, open spaces with minimal support structures.

Steel building workshops stand as engineering marvels, embodying the principles of strength, durability, and adaptability. The structural integrity of these workshops is rooted in the exceptional properties of steel and the innovative engineering techniques employed in their design and construction. As technology continues to advance, the capabilities of steel workshops will only expand, offering even greater possibilities for various industries. Whether for industrial, commercial, or residential use, steel workshops remain a testament to the ingenuity and resilience of modern engineering.